The inside workings of Narrowboat Glass

Nestled right next door to the Venetian main Sales Office is the working glass studio of Narrowboat Glass. They design and make bespoke glass mainly for narrowboats.

They say if you can imagine it in glass for your boat it’s likely they can make it.

Over the course of several blogs we will be taking a closer look at the process from start to finish. Keep an eye out for our future blogs to learn the mystical process of leaded glass and how it’s made for your boat.

Evidence of stained glass windows can be found in Great Britain dating back to the 7th century and amazingly not much has changed in the way stained glass is made today. Although Narrowboat Glass do apply some modern technology it plays a minor role in the creation of the final stained glass project. Today lets begin with the modern technology part. If you’ve got it, use it!

The designing stage

It starts with a discussion of where the glass will be located on the boat, a window, door, porthole, cratch etc... and whether it’s to be a privacy window or whether the owner still wishes to have the view. The design itself can be anything from wildlife to geometric, abstract or traditional. It’s seems really you’re only limited by your imagination.

Once discussed and measurements are known the design is drawn up on a computer in a special CAD program. It’s important to understand the term ‘tight fit’ measurement. When measuring for a project it’s very important to supply the actual tight fit measurement without making any allowances. Narrowboat Glass always build slightly under the supplied measurements to ensure a smooth fit but also to allow for expansion and contraction on a boat.

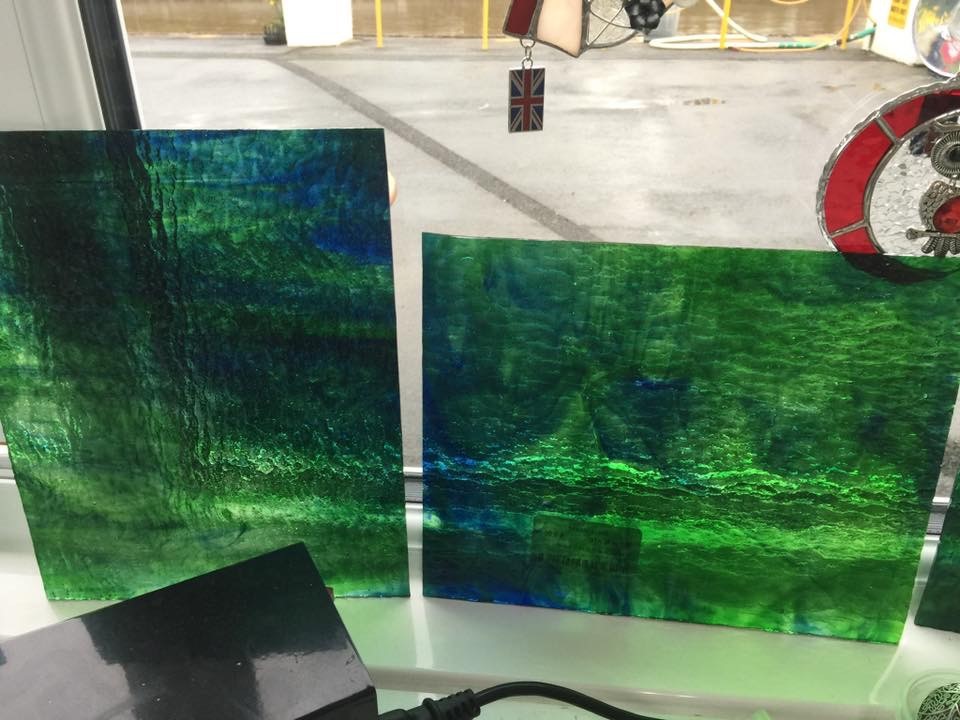

The exciting part is choosing the glass. If you’re ever here to choose glass expect to spend most of the day trying to decide. Luckily you can have lunch next door at Venetian Marina Tea Rooms to fortify these big decisions. There are over 22,000 different types, textures and colours of glass available! It’s both exciting and difficult to narrow it down and decide. Fortunately Narrowboat Glass can take photographs of the actual sheets of glass to be used and add them to the design on the computer giving the customer a generally good idea of what the finished project might look like.

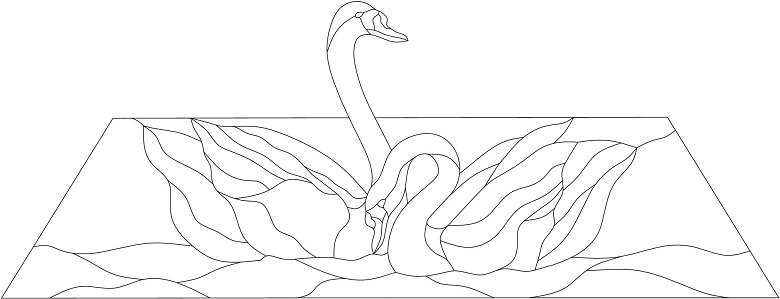

The design before colours are added.

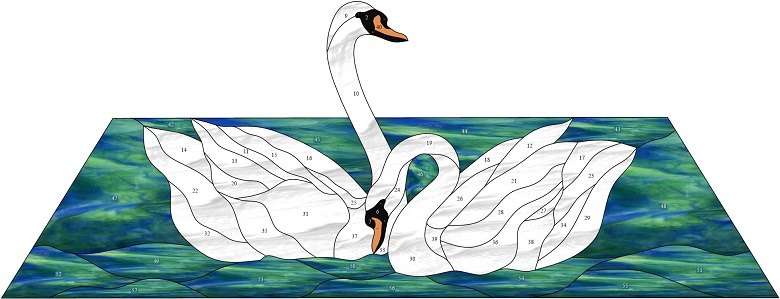

Colours are chosen and added, now it’s important to number all the pieces in the design.

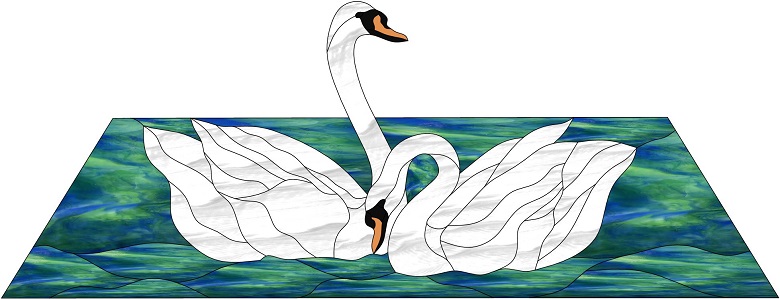

Finally the design is complete and the glass is chosen.

So, how do they build stained glass windows? Join us next time to see how the glass is cut and the project assembled.

See their latest designs at www.NarrowBoatGlass.com